Rotary Vacuum Paddle Dryers (RVPD)

Rotary vacuum paddle Dryer or Paddle Dryer is used to obtain dry Powder from wet cake or solutions. The efficiency is very high and the operating costs are low compared to other types of dryers. It is a closed system in which hot water ,steam, or hot fluid is used as a heating medium in the jacket, in the hollow paddle and in the hallow shaft.

How Rotary vacuum paddle dryer works?

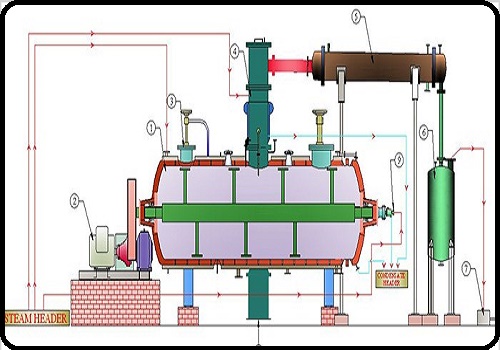

Rotary vacuum dryer is a horizontal cylindrical jacketed shell with

hollow agitator, rotating in close clearance. A batch operation,

drying is done under vacuum, heating is through jacket. The

dryer offers a simple but effective method of drying wet cakes

and sometimes slurries. Due to vacuum and agitation, it is

possible to dry heat sensitive materials.

Advantages

l Uniform drying

l Short cycle time

l No degradation due to over-exposure, more temperature

and time

l Automated discharge, ease of handling, with condenser and

receiver, recovery of solvents

Product Code : RVPD

Features

- Common base frame is unique to this system.

- Drying optimization, this is done by means of external and internal heating.

- Mechanical seals at Shell ends/Stuffing Box.

|

TECHNICAL DATA : |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Our Other product:

Chemical reactor