Ointment manufacturing plant

We Are Leading Manufacturer, Supplier & Exporter Of Cosmetic, Ointment Cream, Cream, Ointment Manufacturing Plant, Cosmetic Manufacturing Plant For Pharmaceuticals Industry, Ointment Mixers For Pharmaceutical Industry, Ointment Process, Ointment Cream Mixer, Ointment Making Vessels, Cream Manufacturing Vessel, Ointment Manufacturing Tank, Ointment Preparation, Automatic Ointment Making Plant, Jacketed, Stainless Steel Storage Tank, Jacketed Mixing Vessel.

The Ointment and cream Manufacturing Plants are 100 % ensure an-touch perfect manufacturing proceeds for the pharmaceutical and corrective businesses for the creation of Ointment, Cream, Lotions, Tooth Paste and different emulsions and homogenization.

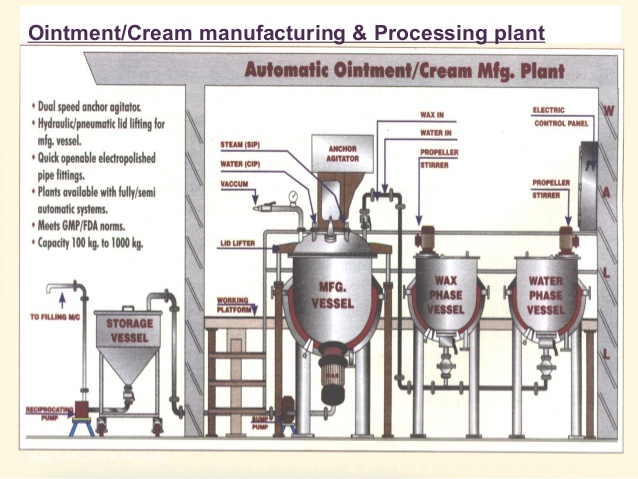

OINTMENT PLANT CONSIST THE FOLLOWING sorts of hardware AND ACCESSORIES.

- Assembling Vessel

- Wax Phase Vessel

- Water Phase Vessel

- Capacity Vessel

- Vacuum Pump

- Control Panel

- Item Piping

- Working Platform

Material Transfer Pump to Transfer material from assembling Vessel to Storage Vessel and Storage Vessel to Ointment ( Tube ) Filling M/C.

This framework comprises of a shut circuit fabricating office from the sustaining of Wax/Water Phase to stacking the container of the filling machine.

The Wax and Water at required temperature are exchanged to Manufacturing Vessel or Planetary Mixer, by vacuum through a tapered channel.

The item amid emulsion arrangement is recycled through Ointment Transfer Pump The Pump likewise releases the item in the Storage Vessel.

The Storage Vessel is then taken to the filling territory and is associated with again Ointment Transfer Pump. Or then again Storage Vessel stays fixed ( In greater size ) and siphon move the treatments in the container of the Ointment Filling Machine.

Cream and ointment manufacturing plant Ointment Manufacturing Plant are ideal tools for the Pharmaceuticals & Cosmetic industries for the production of Ointment, Cream, Lotions, Gels, Shampoo, Toothpaste.

Our Many manufacturing plant for Tooth Paste, Creams, Cosmetics and other viscous materials products

|

Body Care and Cleaning manufacturing plant |

Products Lotions / Creams / Gels |

|

Mixer and Skin Protection Products manufacturing plant |

Mixer and manufacturing plant for Sun Creams and Lotions / Sun Gels |

|

Hair Care Products manufacturing plant / Mixer |

Shampoos manufacturing plant / Mixer |

|

Many other Cosmetics products |

Tooth Paste manufacturing plant / Mixer |

Cosmetic Manufacturers

- L’Oréal

- Unilever

- Estée Lauder

- P&G

- Coty

- Shiseido

- Beiersdorf

- Johnson & Johnson

- AmorePacific

- Kao

- LVMH

- Brands

- Avon

- Henkel

- Mary Kay

- Colgate-Palmolive

- Chanel

- Natura

- Revlon

- Kose

- Patanjali

- Himalaya

Manufacturing Plant Setup for Production

- Shaving Cream Manufacturing Plant

- Contra Rotating Mixer

- Shampoo Manufacturing Plant

- Hair Oil Manufacturing Plant

- Toothpaste Manufacturing Plant

- Talcum Powder Manufacturing Plant

- Planetary Mixer

SAILENT FEATURES :

- The Plant is intended to be worked just by one administrator and one aide.

- Every single material exchange are finished by vacuum or by exchange siphons.

- Every one of the vessels are CGMP (paint free development)

- The gaskets utilized are of silicon (nourishment grade).

- All contact parts are of S.S. 304 quality material (SS316 gave on interest) and completed to class 4B (Mirror) complete and are without cleft.

- The passage of all instigators is from best and High-Speed Emulsifier from a base or In-line Emulsifier ( according to client decision ).

- All vessels are appropriate for an inward weight of 1 Kg. /Sq. cm. what’s more, thus can be cleaned.

- All channels, pipe fittings, and valves are of SS304/SS316 ( according to client prerequisite ) consistent quality, inside electropolished, with tri-clover finished joints.

- The whole plant is furnished with CIP and SIP associations, so client can utilize these offices if have CIP and SIP hardware.

- All estimations of temperature and time of the plant are shown carefully on the control board. Ampere shows on Ampere meters.

- A smaller scale processor based programmed working plant can be structured according to prerequisite.

- All the bay and outlet associations are furnished with tri-clover joints, which are simple for cleaning and substitution.

We are leading manufacturer, supplier & exporter of Automatic Ointment, Automatic Cosmetic Cream, Automatic Cream, Automatic Lotion, Automatic Ointment cream, Cosmetic Cream, Cream, Lotion, Ointment & Pharmaceuticals Ointment manufacturing Plants.